Page 209 - SF ELEC CAT_V4.0_WEB_F2-UPDATE-18-02-19

P. 209

WINDERS – HYDRAULIC

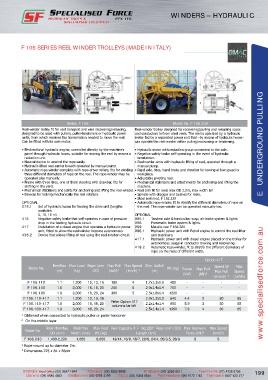

F 106 SERIES REEL WINDER TROLLEYS (MADE IN ITALY)

Series. F 106 Model No. F 106.230

Reel-winder trolley fit for reel transport and wire recovering/releasing, Reel-winder trolley designed for recovering/pulling and releasing ropes

designed to be used with pullers, puller-tensioners or hydraulic power and conductors to/from steel reels. The reel is operated by a hydraulic

units, from which receives the transmission needed to move the reel. motor fed by a separated power unit that –by means of hydraulic hoses–

Can be fitted with its own motor. can operate the reel-winder either pulling/recovering or tensioning. E UNDERGROUND PULLING

• Bi-directional hydraulic engine, controlled directly by the machine’s • Hydraulic motor with reduction group connected to the axle.

panel through hydraulic hoses, suitable for moving the reel by means a • Negative safety brake self-operating in the event of hydraulic

reduction unit. breakdown.

• Neutral device to unwind the rope easily. • Reel-carrier arms with hydraulic lifting of reel, operated through a

• Hydraulic-lifted reel-carrier broach operated by manual pump. manual pump.

• Automatic rope-winder complete with rope-driver rollers, fits for winding • Rigid axle, tires, hand brake and drawbar for towing at low speed in

three different diameters of rope on the reel. The rope-winder may be workplace.

operated also manually. • Adjustable pivoting reel.

• Frame with three tires, one of them steering with drawbar, fits for • Mechanical stabilisers and attachments for anchoring and lifting the

shifting in the yard. machine.

• Mechanical stabilisers and joints for anchoring and lifting the reel-winder. • Reel arm fit for reels max OD 2.2m, max width 1m

• Devices for locking mechanically the reel rotation. • Spindle with dragger and bushes for reels.

• Steel reel mod. F 162.220

OPTIONAL • Automatic rope-winder, fit to stratify the different diameters of rope on

078.1 Set of hydraulic hoses for feeding the drive unit (lengths the reel. The rope-winder can be operated manually too.

available:

5, 10, 15 m). OPTIONAL

416 Negative safety brake that self-operates in case of pressure 005.1 Tandem axle & torsion bar susp, air brake system & lights.

drop in the feeding hydraulic circuit. 006 Pneumatic brake system & lights.

417 Installation of a diesel engine that operates a hydraulic power 059 Metallic reel F 162.220

unit, fitted to allow the reel-winder become autonomous. 096.1 Hydraulic power unit with Petrol engine to control the reel-lifter

438.2 Device that allows lifting of reel using the reel-rotation circuit. and stabilisers.

417.1 Hydraulic power unit with diesel engine placed on the trolley for

autonomous usage in conductor braking and recovering.

419.2 Automatic rope-winder, fit to stratify the different diameters of

rope on the reels of different width.

Option 417

ReelMax Max Load Rope (mm Max Pull Max Speed Dim. AxBxC Speed @ Max

Model No. Wt (kg) Power Max Pull

(m) (kg) OD) (daN)¹ (km/h) ¹ (m) Max Pull Speed

(kW) (kN)²

(m/min) ² (m/Min

F 106.110 1.1 1,200 10, 13, 16 150 4 1.7x1.3x1.0 450 - - - - www.specialisedforce.com.au

F 106.140 1.6 2,000 16, 18, 20 250 5 2.0x1.4x1.4 700 - - - -

F 106.180 1.9 3,000 18, 20, 24 300 5 2.5x1.8x1.4 1200 - - - -

F 106.110-417 1.1 1,200 10, 13, 16 2.0x1.3x1.0 540 4.4 2 30 65

F 106.140-417 1.6 2,000 16, 18, 20 Refer Option 417 2.2x1.4x1.4 800 5.9 3 30 65

columns far left

F 106.180-417 1.9 3,000 18, 20, 24 2.5x1.4x1.4 1350 7.3 4 30 65

¹ Obtained when connected to hydraulic puller or puller-tensioner

² On the middle layer

Reel Min/Max Reel Max Max Reel Reel Capacity # F 162.220² Rope (mm OD)/ Max Recovery Max Speed

Model No.

OD (mm) Width (mm) Wt (kg) Length (km) Force (kN)¹ (km/h)

F 106.230 1,400-2,200 1,000 8,000 13/14, 16/9, 18/7, 20/6, 24/4, 26/3.5, 28/3 5 5

¹ Rope wound up to diameter 2m.

² Dimensions 225 x 84 x 86cm

SYDNEY Head Office (02) 9547 1844 Adelaide (08) 8352 8866 Brisbane (07) 3256 6011 Townsville (07) 4728 8756 199

Darwin (08) 8984 4453 Melbourne (03) 9761 4199 Perth (08) 9354 8544 Port Hedland (08) 9172 1113 Tasmania 0427 423 217