Page 41 - Durapac_2016

P. 41

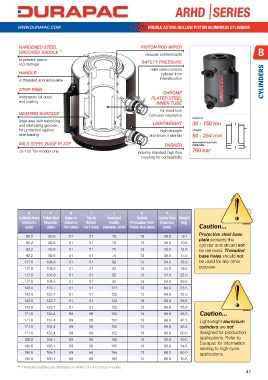

ARHD |SERIES

WWW.DURAPAC.COM DOUBLE ACTING HOLLOW PISTON ALUMINIUM CYLINDERS

hARDENED STEEL PISTON ROD WIPER

GROOvED SADDLE ** reduces contaminants B

to prevent piston SAFETY PRESSURE

rod damage

relief valve protects

hANDLE cylinder from

is threaded and removable intensification CYLINDERS

STOP RING

ChROME

withstands full dead PLATED STEEL

end loading INNER TUBE

for maximum

BEARING SURFACE corrosion resistance

CAPACITY

large area with balancing

and lubricating grooves LIGhTWEIGhT 30 - 150 ton

for protection against high strength STROkE

side loading aluminium materials 50 - 254 mm

MILD STEEL BASE PLATE PARkER MAXIMUM OPERATING

PRESSURE

?

75-150 Ton models only industry standard high flow 700 bar

coupling for compatibility

!

Cylinder Capacity Cylinder Effective Oil Capacity A B D E F H I J K Y

Model Number Stroke Area Collapsed Extended Outside Cylinder Bore Piston Rod Base to Top to Standard Saddle Centre Hole Weight

(mm) Height Height Diameter Diameter Diameter Advance Return Saddle Protrusion from Diameter (kg)

ton* Advance Retract Advance Retract Advance Retract (mm) (mm) (mm) (mm) (mm) Port (mm) Port (mm) Diameter (mm) Piston Rod (mm) (mm) Caution...

3

3

kN kN (cm ) (cm ) (cm ) (cm )

2

2

Protective steel base

?

ARHD-302 287 91 50 40.97 13.03 208 67 191 241 139 92.2 82.6 51 51 70 13 38.0 9.1

i

plate protects the

ARHD-304 287 91 100 40.97 13.03 416 133 242 342 139 92.2 82.6 51 51 70 13 38.0 10.9 cylinder and should not

30

ARHD-306 287 91 152 40.97 13.03 624 200 293 445 139 92.2 82.6 51 51 70 13 38.0 12.6 be removed. Threaded

ARHD-3010 287 91 254 40.97 13.03 1,040 332 394 648 139 92.2 82.6 51 51 70 13 38.0 17.0 base holes should not

ARHD-502 465 155 50 66.45 22.12 337 112 191 241 191 117.6 104.8 51 51 92 13 54.0 15.0 be used for any other

purpose.

ARHD-504 465 155 100 66.45 22.12 675 225 242 342 191 117.6 104.8 51 51 92 13 54.0 18.6

50

ARHD-506 465 155 152 66.45 22.12 1,013 337 293 445 191 117.6 104.8 51 51 92 13 54.0 22.0

ARHD-5010 465 155 254 66.45 22.12 1,689 563 394 648 191 117.6 104.8 51 51 92 13 54.0 29.5

ARHD-752 688 281 50 98.25 40.13 499 203 242 292 228 143.0 123.7 51 51 122 13 69.9 23.5

ARHD-754 688 281 100 98.25 40.13 998 407 293 393 228 143.0 123.7 51 51 122 13 69.9 32.0 !

75

ARHD-756 688 281 152 98.25 40.13 1,497 611 343 495 228 143.0 123.7 51 51 122 13 69.9 38.5

ARHD-7510 688 281 254 98.25 40.13 2,495 1,019 445 699 228 143.0 123.7 51 51 122 13 69.9 45.3

ARHD-1002 975 339 50 139.29 48.45 707 246 254 304 279 171.6 152.4 69 56 152 13 88.9 38.5 Caution...

ARHD-1004 975 339 100 139.29 48.45 1,415 492 305 405 279 171.6 152.4 69 56 152 13 88.9 42.3 Lightweight aluminium

i

100

ARHD-1006 975 339 152 139.29 48.45 2,123 738 355 507 279 171.6 152.4 69 56 152 13 88.9 46.4 cylinders are not

ARHD-10010 975 339 254 139.29 48.45 3,539 1,230 457 711 279 171.6 152.4 69 69 152 13 88.9 60.0 designed for production

ARHD-1502 1,421 497 50 203.03 70.96 1,004 295 254 304 304 190.6 165.1 69 56 165 13 88.9 49.0 applications. Refer to

ARHD-1504 1,421 497 100 203.03 70.96 2,008 590 305 405 304 190.6 165.1 69 56 165 13 88.9 54.8 Durapac for information

150 relating to high cycle

ARHD-1506 1,421 497 152 203.03 70.96 3,012 885 355 507 304 190.6 165.1 69 56 165 13 88.9 60.0 applications.

ARHD-15010 1,421 497 254 203.03 70.96 5,021 1,475 457 711 304 190.6 165.1 69 69 165 13 88.9 70.8

** Threaded saddles are standard on ARHD 30 and 50 ton models

41