Page 37 - Durapac_2016

P. 37

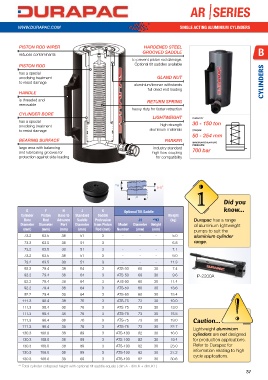

AR |SERIES

WWW.DURAPAC.COM SINGLE ACTING ALUMINIUM CYLINDERS

PISTON ROD WIPER hARDENED STEEL

GROOvED SADDLE B

reduces contaminants

to prevent piston rod damage.

PISTON ROD Optional tilt saddles available

has a special

anodising treatment GLAND NUT

to resist damage CYLINDERS

aluminium/bronze withstands

full dead end loading

hANDLE

is threaded and RETURN SPRING

removable ?

heavy duty for faster retraction

CYLINDER BORE

LIGhTWEIGhT CAPACITY

has a special 30 - 150 ton

anodising treatment high strength

to resist damage aluminium materials STROkE

50 - 254 mm

BEARING SURFACE PARkER MAXIMUM OPERATING

PRESSURE

large area with balancing industry standard !

and lubricating grooves for high flow coupling 700 bar

protection against side loading for compatibility

i

**K1

0-5 °

J1 Did you

A B D E F H J K Optional Tilt Saddle know...

Model Number Cylinder Capacity Stroke Cylinder Oil Collapsed Extended Outside Cylinder Piston Base to Standard Saddle Weight

ton* / kN (mm) Effective Area Capacity Height Height Diameter Bore Rod Advance Saddle Protrusion J1 **K1 (kg) Durapac has a range

(cm ) (cm ) (mm) (mm) (mm) Diameter Diameter Port Diameter from Piston Model Diameter Height of aluminium lightweight

3

2

(mm) (mm) (mm) (mm) Rod (mm) Number (mm) (mm) pumps to suit the

AR-302 293 50 41.9 213 168 218 114 73.2 63.5 38 51 3 - - - 5.0 aluminium cylinder

AR-304 293 101 41.9 426 229 330 114 73.2 63.5 38 51 3 - - - 6.8 range.

AR-306 30 293 152 41.9 639 270 422 114 73.2 63.5 38 51 3 - - - 7.1

AR-308 293 203 41.9 852 320 523 114 73.2 63.5 38 51 3 - - - 9.0

AR-3010 293 254 41.9 1,065 371 625 114 73.2 63.5 38 51 3 - - - 11.3 ?

AR-502 498 50 71.2 360 168 218 139 92.2 79.4 38 64 3 ATS-50 60 30 7.4

AR-504 498 101 71.2 723 229 330 139 92.2 79.4 38 64 3 ATS-50 60 30 9.6 P-2200A

AR-506 50 498 152 71.2 1,085 270 422 139 92.2 79.4 38 64 3 ATS-50 60 30 11.4

AR-508 498 203 71.2 1,445 320 523 139 92.2 79.4 38 64 3 ATS-50 60 30 13.6

AR-5010 498 254 71.2 1,809 371 625 139 92.2 79.4 38 64 3 ATS-50 60 30 15.4

AR-752 678 50 96.8 492 168 218 165 111.3 98.4 38 76 3 ATS-75 73 30 10.0

AR-754 678 101 96.8 985 229 330 165 111.3 98.4 38 76 3 ATS-75 73 30 13.0 !

AR-756 75 678 152 96.8 1,477 270 422 165 111.3 98.4 38 76 3 ATS-75 73 30 15.8

AR-758 678 203 96.8 1,969 320 523 165 111.3 98.4 38 76 3 ATS-75 73 30 19.0 Caution...

AR-7510 678 254 96.8 2,463 371 625 165 111.3 98.4 38 76 3 ATS-75 73 30 22.7

Lightweight aluminium

AR-1002 931 50 133.0 675 168 218 203 130.3 108.0 38 89 3 ATS-100 82 30 16.0 cylinders are not designed

AR-1004 931 101 133.0 1,351 229 330 203 130.3 108.0 38 89 3 ATS-100 82 30 19.4 for production applications.

AR-1006 100 931 152 133.0 2,027 270 422 203 130.3 108.0 38 89 3 ATS-100 82 30 23.0 Refer to Durapac for i

AR-1008 931 203 133.0 2,702 320 523 203 130.3 108.0 38 89 3 ATS-100 82 30 27.2 information relating to high

cycle applications.

AR-10010 931 254 133.0 3,379 371 625 203 130.3 108.0 38 89 3 ATS-100 82 30 30.6

** Total cylinder collapsed height with optional tilt saddle equals ( dim.A - dim.K + dim.K1 )

37