Page 45 - Durapac_2016

P. 45

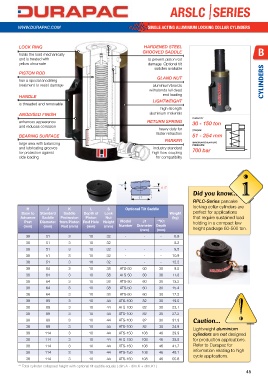

ARSLC |SERIES

WWW.DURAPAC.COM SINGLE ACTING ALUMINIUM LOCKING COLLAR CYLINDERS

LOCk RING hARDENED STEEL

GROOvED SADDLE B

holds the load mechanically

and is treated with to prevent piston rod

yellow chromate damage. Optional tilt

saddles available

PISTON ROD

GLAND NUT

has a special anodising CYLINDERS

treatment to resist damage aluminium/bronze

withstands full dead

hANDLE end loading ?

LIGhTWEIGhT

is threaded and removable

high strength

ANODISED FINISh aluminium materials

CAPACITY

enhances appearance RETURN SPRING 30 - 150 ton

and reduces corrosion

heavy duty for STROkE

faster retraction

BEARING SURFACE 51 - 254 mm !

PARkER

large area with balancing MAXIMUM OPERATING

PRESSURE

and lubricating grooves industry standard

for protection against high flow coupling 700 bar

side loading for compatibility

Did you know...i

**K1

0-5˚

J1

RPLC-Series pancake

locking collar cylinders are

A B D E F H J K L S Optional Tilt Saddle

Model Number Cylinder Stroke Cylinder Oil Collapsed Extended Outside Cylinder Piston Rod Base to Standard Saddle Depth of Lock Weight perfect for applications

Capacity (mm) Effective Capacity Height Height Diameter Bore Diameter Advance Saddle Protrusion Piston Nut (kg) that require sustained load

3

ton* / kN Area (cm ) (mm) (mm) (mm) Diameter (mm) Port Diameter from Piston Rod Hole Height Model J1 **K1 holding in a compact low

(cm ) (mm) (mm) (mm) Rod (mm) (mm) (mm) Number Diameter Depth height package 60-500 ton.

2

(mm) (mm)

ARSLC-302 294 51 41.94 213 197 248 114 73 63.5 38 51 3 10 32 - - - 6.8

ARSLC-304 294 102 41.94 426 248 349 114 73 63.5 38 51 3 10 32 - - - 8.2

ARSLC-306 30 294 152 41.94 639 299 451 114 73 63.5 38 51 3 10 32 - - - 9.5

ARSLC-308 294 203 41.94 852 350 552 114 73 63.5 38 51 3 10 32 - - - 10.9

ARSLC-3010 294 254 41.94 1,065 401 654 114 73 63.5 38 51 3 10 32 - - - 12.2 ?

ARSLC-502 499 51 71.23 355 207 257 140 95 79.4 38 64 3 10 38 ATS-50 60 30 9.5

ARSLC-504 499 102 71.23 710 258 359 140 95 79.4 38 64 3 10 38 ATS-50 60 30 11.8

ARSLC-506 50 499 152 71.23 1,064 308 460 140 95 79.4 38 64 3 10 38 ATS-50 60 30 13.2

ARSLC-508 499 203 71.23 1,418 359 562 140 95 79.4 38 64 3 10 38 ATS-50 60 30 15.4

ARSLC-5010 499 254 71.23 1,773 410 664 140 95 79.4 38 64 3 10 38 ATS-50 60 30 17.2

ARSLC-1002 934 51 133.42 664 213 264 203 130 108.0 38 89 3 10 44 ATS-100 82 30 19.5

ARSLC-1004 934 102 133.42 1,327 264 365 203 130 108.0 38 89 3 10 44 ATS-100 82 30 23.1 !

ARSLC-1006 100 934 152 133.42 1,991 315 467 203 130 108.0 38 89 3 10 44 ATS-100 82 30 27.2

ARSLC-1008 934 203 133.42 2,655 366 568 203 130 108.0 38 89 3 10 44 ATS-100 82 30 31.3 Caution...

ARSLC-10010 934 254 133.42 3,318 416 670 203 130 108.0 38 89 3 10 44 ATS-100 82 30 34.9

Lightweight aluminium

ARSLC-1502 1,386 51 197.94 993 213 264 254 159 127.0 38 114 3 10 44 ATS-150 108 46 29.9 cylinders are not designed

i

ARSLC-1504 1,386 102 197.94 1,986 264 365 254 159 127.0 38 114 3 10 44 ATS-150 108 46 35.8 for production applications.

ARSLC-1506 150 1,386 152 197.94 2,979 315 467 254 159 127.0 38 114 3 10 44 ATS-150 108 46 41.7 Refer to Durapac for

ARSLC-1508 1,386 203 197.94 3,972 366 568 254 159 127.0 38 114 3 10 44 ATS-150 108 46 48.1 information relating to high

cycle applications.

ARSLC-15010 1,386 254 197.94 4,965 416 670 254 159 127.0 38 114 3 10 44 ATS-150 108 46 55.8

** Total cylinder collapsed height with optional tilt saddle equals ( dim.A - dim.K + dim.K1 )

45