Page 43 - Durapac_2016

P. 43

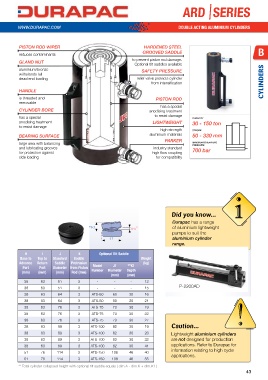

ARD |SERIES

WWW.DURAPAC.COM DOUBLE ACTING ALUMINIUM CYLINDERS

PISTON ROD WIPER hARDENED STEEL

GROOvED SADDLE B

reduces contaminants

to prevent piston rod damage.

GLAND NUT Optional tilt saddles available

aluminium/bronze SAFETY PRESSURE

withstands full

dead end loading relief valve protects cylinder

from intensification CYLINDERS

hANDLE

is threaded and PISTON ROD

removable

has a special

CYLINDER BORE anodising treatment

has a special to resist damage CAPACITY ?

anodising treatment LIGhTWEIGhT 30 - 150 ton

to resist damage

high strength STROkE

BEARING SURFACE aluminium materials 50 - 330 mm

PARkER

large area with balancing MAXIMUM OPERATING

PRESSURE

and lubricating grooves industry standard

!

for protection against high flow coupling 700 bar

side loading for compatibility

i

Did you know...

Durapac has a range

**K1 0-5 ° of aluminium lightweight

pumps to suit the

J1 aluminium cylinder

range.

Cylinder Capacity Cylinder Effective Oil Capacity A B D E F H I J K Optional Tilt Saddle

Model Stroke Area Collapsed Extended Outside Cylinder Piston Base to Top to Standard Saddle Weight

Number (mm) Height Height Diameter Bore Rod Advance Return Saddle Protrusion (kg)

ton* Advance Retract Advance Retract Advance Retract (mm) (mm) (mm) Diameter Diameter Port Port Diameter from Piston Model J1 **K1 ?

2

3

2

kN kN (cm ) (cm ) (cm ) (cm ) (mm) (mm) (mm) (mm) (mm) Rod (mm) Number Diameter Depth

3

(mm) (mm)

ARD-308 293 114 203 41.9 16.3 850 295 349 552 114 73.2 63.5 38 63 51 3 - - - 12

30 P-2200AD

ARD-3013 293 114 330 41.9 16.3 1,488 578 476 806 114 73.2 63.5 38 63 51 3 - - - 15

ARD-508 535 124 203 76.4 17.7 1,447 360 349 552 139 92.2 79.4 38 63 64 3 ATS-50 60 30 16

50

ARD-5013 535 124 330 76.4 17.7 2,351 585 476 806 139 92.2 79.4 38 63 64 3 ATS-50 60 30 21

ARD-756 679 146 152 97.0 20.9 1,477 318 312 450 165 111.3 98.4 38 63 76 3 ATS-75 73 30 19

ARD-758 75 679 146 203 97.0 20.9 1,971 710 356 559 165 111.3 98.4 38 63 76 3 ATS-75 73 30 22 !

ARD-7513 679 146 330 97.0 20.9 3,201 690 490 806 165 111.3 98.4 38 63 76 3 ATS-75 73 30 27

ARD-1002 931 220 50 133.0 31.4 675 154 211 246 203 130.3 108.0 38 63 89 3 ATS-100 82 30 19 Caution...

ARD-1006 931 220 152 133.0 31.4 2,027 464 311 463 203 130.3 108.0 38 63 89 3 ATS-100 82 30 26 Lightweight aluminium cylinders

100

ARD-1008 931 220 203 133.0 31.4 2,705 620 356 559 203 130.3 108.0 38 63 89 3 ATS-100 82 30 32 are not designed for production

ARD-10013 931 220 330 133.0 31.4 4,392 1,005 488 818 203 130.3 108.0 38 63 89 3 ATS-100 82 30 41 applications. Refer to Durapac for

information relating to high cycle

ARD-1506 1,386 313 152 198.0 44.7 3,016 681 363 488 254 158.9 127.0 51 76 114 3 ATS-150 108 46 40

150 applications. i

ARD-15013 1,386 313 330 198.0 44.7 6,535 1,476 541 844 254 158.9 127.0 51 76 114 3 ATS-150 108 46 55

** Total cylinder collapsed height with optional tilt saddle equals ( dim.A - dim.K + dim.K1 )

43