Page 32 - Durapac_2016

P. 32

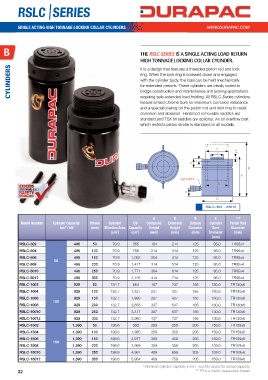

RSLC |SERIES

SINGLE ACTING HIGH TONNAGE LOCKING COLLAR CYLINDERS WWW.DURAPAC.COM

B thE rSLc-SerIeS is a siNGLE actiNG LoaD rEturN

hiGh toNNaGE LocKiNG coLLar cyLiNDEr.

CYLINDERS ring. When the lock ring is screwed down and engaged

It is a design that features a threaded piston rod and lock

with the cylinder body, the load can be held mechanically

for extended periods. These cylinders are ideally suited to

bridge construction and maintenance and jacking applications

requiring safe extended load holding. All RSLC-Series cylinders

feature a hard chrome bore for maximum corrosion resistance

and a special coating on the piston rod and lock ring to resist

corrosion and abrasion. Hardened removable saddles are

standard and TSX tilt saddles are optional. An oil overflow port

which restricts piston stroke is standard on all models.

F K

J

L

S

B

A

3/8"-NPTF

E

H

D

RSLC-502 - 25012

A B D E **F H J K L S Optional Tilt Saddle

Model Number Cylinder Capacity Stroke Cylinder Oil Collapsed Extended Outside Cylinder Piston Rod Base to Standard Saddle Depth of Lock Ring Weight Model Number Handle

ton* / kN (mm) Effective Area Capacity Height Height Diameter Bore Diameter Advance Saddle Protrusion from Piston Rod Height (kg) J1 ***K1 Type

(cm ) (cm ) (mm) (mm) (mm) Diameter (mm) Port (mm) Diameter Piston Rod Hole (mm) (mm) Model Diameter Height

3

2

(mm) (mm) (mm) Number (mm) (mm)

RSLC-502 496 50 70.9 355 164 214 125 95.0 TR95x4 30 71 2 13 36 15.0 TSX-100 71 24 RSLC-502 ♦

RSLC-504 496 100 70.9 708 214 314 125 95.0 TR95x4 30 71 2 13 36 20.0 TSX-100 71 24 RSLC-504 ♦

RSLC-506 496 150 70.9 1,063 264 414 125 95.0 TR95x4 30 71 2 13 36 25.0 TSX-100 71 24 RSLC-506 ♦

50

RSLC-508 496 200 70.9 1,417 314 514 125 95.0 TR95x4 30 71 2 13 36 30.0 TSX-100 71 24 RSLC-508 ♦

RSLC-5010 496 250 70.9 1,771 364 614 125 95.0 TR95x4 30 71 2 13 36 35.0 TSX-100 71 24 RSLC-5010 ♦

RSLC-5012 496 300 70.9 2,125 414 714 125 95.0 TR95x4 30 71 2 13 36 40.0 TSX-100 71 24 RSLC-5012 ♦

RSLC-1002 929 50 132.7 664 187 237 165 130.0 TR130x6 30 71 2 13 44 30.0 TSX-100 71 24 RSLC-1002 ♦

RSLC-1004 929 100 132.7 1,327 237 337 165 130.0 TR130x6 30 71 2 13 44 39.0 TSX-100 71 24 RSLC-1004 ♦

RSLC-1006 929 150 132.7 1,990 287 437 165 130.0 TR130x6 30 71 2 13 44 48.0 TSX-100 71 24 RSLC-1006 ♦

100

RSLC-1008 929 200 132.7 2,653 337 537 165 130.0 TR130x6 30 71 2 13 44 56.0 TSX-100 71 24 RSLC-1008 ♦

RSLC-10010 929 250 132.7 3,317 387 637 165 130.0 TR130x6 30 71 2 13 44 64.0 TSX-100 71 24 RSLC-10010 ♦

RSLC-10012 929 300 132.7 3,980 437 737 165 130.0 TR130x6 30 71 2 13 44 73.0 TSX-100 71 24 RSLC-10012 ♦

RSLC-1502 1,390 50 198.6 993 209 259 205 159.0 TR159x6 39 130 2 25 44 53.0 TSX-200 130 20 RSLC-1502 ♦

RSLC-1504 1,390 100 198.6 1,985 259 359 205 159.0 TR159x6 39 130 2 25 44 66.0 TSX-200 130 20 RSLC-1504 ♦

RSLC-1506 1,390 150 198.6 2,977 309 459 205 159.0 TR159x6 39 130 2 25 44 78.0 TSX-200 130 20 RSLC-1506 ♦

150

RSLC-1508 1,390 200 198.6 3,969 359 559 205 159.0 TR159x6 39 130 2 25 44 92.0 TSX-200 130 20 RSLC-1508 ♦

RSLC-15010 1,390 250 198.6 4,961 409 659 205 159.0 TR159x6 39 130 2 25 44 104.0 TSX-200 130 20 RSLC-15010 ♦

RSLC-15012 1,390 300 198.6 5,954 459 759 205 159.0 TR159x6 39 130 2 25 44 117.0 TSX-200 130 20 RSLC-15012 ♦

* Nominal Cylinder Capacity in ton - see kN values for actual capacity

32 ** TR is a metric trapezoidal thread