Page 55 - Durapac_2016

P. 55

?

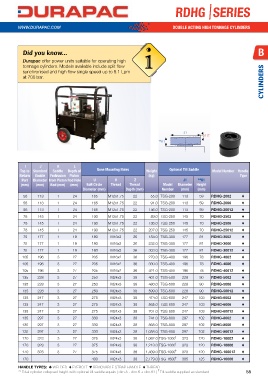

! RDHG |SERIES

WWW.DURAPAC.COM DOUBLE ACTING HIGH TONNAGE CYLINDERS

Did you know... i B

Durapac offer power units suitable for operating high

tonnage cylinders. Models available include split flow

CYLINDERS

synchronised and high flow single speed up to 8.1 Lpm

at 700 bar.

J1

0-5˚

**K1

Cylinder Effective A B D E F H I J K L

Model Number Cylinder Capacity Stroke Area Oil Capacity Collapsed Extended Outside Cylinder Piston Base to Top to Standard Saddle Depth of Base Mounting Holes Weight Optional Tilt Saddle Model Number Handle

(mm) Height Height Diameter Bore Rod Advance Return Saddle Protrusion Piston (kg) Type

ton* Advance Retract Advance Retract Advance Retract (mm) (mm) (mm) Diameter Diameter Port (mm) Port Diameter from Piston Rod Hole U V Z J1 **K1

kN kN (cm 2 ) (cm ) (cm ) (cm ) (mm) (mm) (mm) (mm) Rod (mm) (mm) Bolt Circle Thread Thread Model Diameter Height

3

3

2

Diameter (mm) Depth (mm) Number (mm) (mm)

RDHG-2002 1,861 889 50 265.8 126.7 1,329 634 216 266 235 184.0 133.1 67 56 113 1 24 165 M12x1.75 22 55.0 TSG-200 113 59 RDHG-2002 ♦

RDHG-2006 200 1,861 889 150 265.8 126.7 3,987 1,901 316 466 235 184.0 133.1 67 56 113 1 24 165 M12x1.75 22 91.0 TSG-200 113 59 RDHG-2006 ♦

RDHG-20012 1,861 889 300 265.8 126.7 7,973 3,801 466 766 235 184.0 133.1 67 56 113 1 24 165 M12x1.75 22 146.0 TSG-200 113 59 RDHG-20012 ♦

RDHG-2502 2,565 1,068 50 366.2 152.3 1,831 761 235 285 275 216.0 165.1 73 78 145 1 24 190 M12x1.75 22 89.0 TSG-250 145 70 RDHG-2502 ♦

RDHG-2506 250 2,565 1,068 150 366.2 152.3 5,494 2,284 335 485 275 216.0 165.1 73 78 145 1 24 190 M12x1.75 22 136.0 TSG-250 145 70 RDHG-2506 ♦

RDHG-25012 2,565 1,068 300 366.2 152.3 10,987 4,568 485 785 275 216.0 165.1 73 78 145 1 24 190 M12x1.75 22 207.0 TSG-250 145 70 RDHG-25012 ♦

RDHG-3002 3,193 1,060 50 455.9 151.0 2,280 755 312 362 310 241.0 197.1 101 75 177 1 19 180 M16x2 36 184.0 TSG-300 177 81 RDHG-3002 ♦

RDHG-3006 300 3,193 1,060 150 455.9 151.0 6,839 2,264 412 562 310 241.0 197.1 101 75 177 1 19 180 M16x2 36 232.0 TSG-300 177 81 RDHG-3006 ♦

RDHG-30012 3,193 1,060 300 455.9 151.0 13,678 4,529 562 862 310 241.0 197.1 101 75 177 1 19 180 M16x2 36 303.0 TSG-300 177 81 RDHG-30012 ♦

RDHG-4002 3,919 1,354 50 559.6 193.7 2,798 969 374 424 350 267.0 215.9 114 105 196 3 27 205 M16x2 36 270.0 TSG-400 196 78 RDHG-4002 ♦

RDHG-4006 400 3,919 1,354 150 559.6 193.7 8,394 2,906 474 625 350 267.0 215.9 114 105 196 3 27 205 M16x2 36 330.0 TSG-400 196 78 RDHG-4006 ♦

RDHG-40012 3,919 1,354 300 559.6 193.7 16,789 5,811 624 924 350 267.0 215.9 114 105 196 3 27 205 M16x2 36 421.0 TSG-400 196 78 RDHG-40012 ♦

RDHG-5002 5,114 1,733 50 730.2 247.8 3,651 1,239 419 469 400 305.0 247.9 114 135 228 3 27 250 M24x3 38 401.0 TSG-500 228 90 RDHG-5002 ♦

RDHG-5006 500 5,114 1,733 150 730.2 247.8 10,954 3,717 519 669 400 305.0 247.9 114 135 228 3 27 250 M24x3 38 480.0 TSG-500 228 90 RDHG-5006 ♦

RDHG-50012 5,114 1,733 300 730.2 247.8 21,907 7,434 669 969 400 305.0 247.9 114 135 228 3 27 250 M24x3 38 599.0 TSG-500 228 90 RDHG-50012 ♦

RDHG-6002 5,987 2,068 50 854.9 295.4 4,274 1,477 429 479 430 330.0 267.0 114 135 247 3 27 275 M24x3 38 474.0 TSG-600 247 103 RDHG-6002 ♦

RDHG-6006 600 5,987 2,068 150 854.9 295.4 12,823 4,432 529 679 430 330.0 267.0 114 135 247 3 27 275 M24x3 38 565.0 TSG-600 247 103 RDHG-6006 ♦

RDHG-60012 5,987 2,068 300 854.9 295.4 25,646 8,863 679 979 430 330.0 267.0 114 135 247 3 27 275 M24x3 38 701.0 TSG-600 247 103 RDHG-60012 ♦

RDHG-8002 8,234 2,709 50 1,175.7 386.9 5,878 1,934 474 524 505 387.0 317.0 149 135 297 3 27 330 M24x3 38 741.0 TSG-800 297 102 RDHG-8002 ♦

RDHG-8006 800 8,234 2,709 150 1,175.7 386.9 17,635 5,803 574 724 505 387.0 317.0 149 135 297 3 27 330 M24x3 38 868.0 TSG-800 297 102 RDHG-8006 ♦

RDHG-80012 8,234 2,709 300 1,175.7 386.9 35,271 11,607 724 1,024 505 387.0 317.0 149 135 297 3 27 330 M24x3 38 1,058.0 TSG-800 297 102 RDHG-80012 ♦

RDHG-10002 10,260 3,792 50 1,465.0 542.0 7,325 2,710 564 614 560 432.0 342.9 174 170 323 3 27 375 M24x3 38 1,062.0 TSG-1000 † 323 120 RDHG-10002 ♦

†

RDHG-10006 1,000 10,260 3,792 150 1,465.0 542.0 21,975 8,130 664 814 560 432.0 342.9 174 170 323 3 27 375 M24x3 38 1,213.0 TSG-1000 † 323 120 RDHG-10006 ♦

RDHG-100012 10,260 3,792 300 1,465.0 542.0 43,950 16,260 814 1,114 560 432.0 342.9 174 170 323 3 27 375 M24x3 38 1,439.0 TSG-1000 † 323 120 RDHG-100012 ♦

†

RDHG-16006 1,600 15,703 4,798 155 2,289.2 699.5 35,466 10,836 825 980 710 540.0 450.1 205 170 - - - 400 M24x3 30 2,179.0 TSG-1600 † 385 125 RDHG-16006 ♦

HANDLE TYPES: ♣ WELDED ♦ EYEBOLT ♥ REMOVABLE STRAP HANDLE ♠ THREAD

†

** Total cylinder collapsed height with optional tilt saddle equals ( dim.A - dim.K + dim.K1 ) Tilt saddle supplied as standard 55