Page 52 - Durapac_2016

P. 52

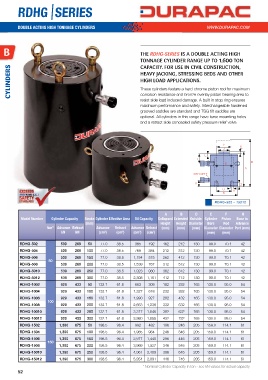

RDHG |SERIES

DOUBLE ACTING HIGH TONNAGE CYLINDERS WWW.DURAPAC.COM

B thE rDHg-SerIeS is a DoubLE actiNG hiGh

toNNaGE cyLiNDEr raNGE up to 1,600 toN

capacity. for usE iN civiL coNstructioN,

CYLINDERS hEavy jacKiNG, strEssiNG bEDs aND othEr

hiGh LoaD appLicatioNs.

These cylinders feature a hard chrome piston rod for maximum

corrosion resistance and bronze overlay piston bearing area to

resist side load induced damage. A built in stop ring ensures

maximum performance and safety. Interchangeable hardened

grooved saddles are standard and TSG tilt saddles are

optional. All cylinders in this range have base mounting holes

and a retract side concealed safety pressure relief valve.

F K

J

L

I

E B

A

3/8"-NPTF

H Z

U V

D

RDhG-502 - 15012

A B D E F H I J K L

Model Number Cylinder Capacity Stroke Cylinder Effective Area Oil Capacity Collapsed Extended Outside Cylinder Piston Base to Top to Standard Saddle Depth of Base Mounting Holes Weight Optional Tilt Saddle Model Number Handle

(mm) Height Height Diameter Bore Rod Advance Return Saddle Protrusion Piston (kg) Type

ton* Advance Retract Advance Retract Advance Retract (mm) (mm) (mm) Diameter Diameter Port (mm) Port Diameter from Piston Rod Hole U V Z J1 **K1

kN kN (cm ) (cm ) 2 (cm ) (cm ) (mm) (mm) (mm) (mm) Rod (mm) (mm) Bolt Circle Thread Thread Model Diameter Height

3

2

3

Diameter (mm) Depth (mm) Number (mm) (mm)

RDHG-502 539 269 50 77.0 38.5 385 192 162 212 130 99.0 70.1 42 33 50 1 19 65 M12x1.75 22 17.0 TSG-50 50 43 RDHG-502 ♦

RDHG-504 539 269 100 77.0 38.5 769 384 212 312 130 99.0 70.1 42 33 50 1 19 65 M12x1.75 22 20.0 TSG-50 50 43 RDHG-504 ♦

RDHG-506 539 269 150 77.0 38.5 1,154 575 262 412 130 99.0 70.1 42 33 50 1 19 65 M12x1.75 22 23.0 TSG-50 50 43 RDHG-506 ♦

50

RDHG-508 539 269 200 77.0 38.5 1,539 767 312 512 130 99.0 70.1 42 33 50 1 19 65 M12x1.75 22 27.0 TSG-50 50 43 RDHG-508 ♦

RDHG-5010 539 269 250 77.0 38.5 1,923 980 362 612 130 99.0 70.1 42 33 50 1 19 65 M12x1.75 22 31.0 TSG-50 50 43 RDHG-5010 ♦

RDHG-5012 539 269 300 77.0 38.5 2,308 1,151 412 712 130 99.0 70.1 42 33 50 1 19 65 M12x1.75 22 34.0 TSG-50 50 43 RDHG-5012 ♦

RDHG-1002 929 433 50 132.7 61.8 663 309 182 232 165 130.0 95.0 54 48 75 1 19 95 M12x1.75 22 29.0 TSG-100 75 48 RDHG-1002 ♦

RDHG-1004 929 433 100 132.7 61.8 1,327 618 232 332 165 130.0 95.0 54 48 75 1 19 95 M12x1.75 22 34.0 TSG-100 75 48 RDHG-1004 ♦

RDHG-1006 929 433 150 132.7 61.8 1,990 927 282 432 165 130.0 95.0 54 48 75 1 19 95 M12x1.75 22 40.0 TSG-100 75 48 RDHG-1006 ♦

100

RDHG-1008 929 433 200 132.7 61.8 2,653 1,236 332 532 165 130.0 95.0 54 48 75 1 19 95 M12x1.75 22 46.0 TSG-100 75 48 RDHG-1008 ♦

RDHG-10010 929 433 250 132.7 61.8 3,317 1,546 382 632 165 130.0 95.0 54 48 75 1 19 95 M12x1.75 22 52.0 TSG-100 75 48 RDHG-10010 ♦

RDHG-10012 929 433 300 132.7 61.8 3,980 1,855 432 732 165 130.0 95.0 54 48 75 1 19 95 M12x1.75 22 58.0 TSG-100 75 48 RDHG-10012 ♦

RDHG-1502 1,390 675 50 198.5 96.4 992 482 196 246 205 159.0 114.1 61 56 94 1 19 130 M12x1.75 22 39.0 TSG-150 94 50 RDHG-1502 ♦

RDHG-1504 1,390 675 100 198.5 96.4 1,985 964 246 346 205 159.0 114.1 61 56 94 1 19 130 M12x1.75 22 52.0 TSG-150 94 50 RDHG-1504 ♦

RDHG-1506 1,390 675 150 198.5 96.4 2,977 1,445 296 446 205 159.0 114.1 61 56 94 1 19 130 M12x1.75 22 65.0 TSG-150 94 50 RDHG-1506 ♦

150

RDHG-1508 1,390 675 200 198.5 96.4 3,969 1,927 346 546 205 159.0 114.1 61 56 94 1 19 130 M12x1.75 22 78.0 TSG-150 94 50 RDHG-1508 ♦

RDHG-15010 1,390 675 250 198.5 96.4 4,961 2,409 396 646 205 159.0 114.1 61 56 94 1 19 130 M12x1.75 22 92.0 TSG-150 94 50 RDHG-15010 ♦

RDHG-15012 1,390 675 300 198.5 96.4 5,954 2,891 446 746 205 159.0 114.1 61 56 94 1 19 130 M12x1.75 22 105.0 TSG-150 94 50 RDHG-15012 ♦

* Nominal Cylinder Capacity in ton - see kN values for actual capacity

52