Page 58 - Durapac_2016

P. 58

!

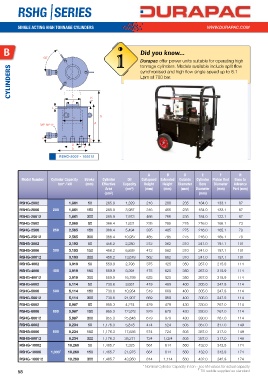

RSHG |SERIES ?

SINGLE ACTING HIGH TONNAGE CYLINDERS WWW.DURAPAC.COM

B i Did you know...

60˚ Durapac offer power units suitable for operating high

tonnage cylinders. Models available include split flow

CYLINDERS synchronised and high flow single speed up to 8.1

Lpm at 700 bar.

J F K

L

B

E

3/8"-NPTF A

H

Z

U V

D

RShG-2002 - 100012

A B D E F H J K L Base Mounting Holes Optional Tilt Saddle

Model Number Cylinder Capacity Stroke Cylinder Oil Collapsed Extended Outside Cylinder Piston Rod Base to Standard Saddle Depth of Weight Model Number Handle

ton* / kN (mm) Effective Capacity Height Height Diameter Bore Diameter Advance Saddle Protrusion Piston U V Z (kg) J1 **K1 Type

Area (cm 3 ) (mm) (mm) (mm) Diameter (mm) Port (mm) Diameter from Piston Rod Hole Bolt Circle Thread Thread Model Diameter Height

(cm 2 ) (mm) (mm) Rod (mm) (mm) Diameter Depth Number (mm) (mm)

(mm) (mm)

RSHG-2002 1,861 50 265.9 1,329 216 266 235 184.0 133.1 67 113 1 24 165 M12x1.75 22 55.0 TSG-200 113 59 RSHG-2002 ♦

RSHG-2006 200 1,861 150 265.9 3,987 316 466 235 184.0 133.1 67 113 1 24 165 M12x1.75 22 91.0 TSG-200 113 59 RSHG-2006 ♦

RSHG-20012 1,861 300 265.9 7,973 466 766 235 184.0 133.1 67 113 1 24 165 M12x1.75 22 146.0 TSG-200 113 59 RSHG-20012 ♦

RSHG-2502 2,565 50 366.4 1,831 235 285 275 216.0 165.1 73 145 1 24 190 M12x1.75 22 102.0 TSG-250 145 70 RSHG-2502 ♦

RSHG-2506 250 2,565 150 366.4 5,494 335 485 275 216.0 165.1 73 145 1 24 190 M12x1.75 22 136.0 TSG-250 145 70 RSHG-2506 ♦

RSHG-25012 2,565 300 366.4 10,987 485 785 275 216.0 165.1 73 145 1 24 190 M12x1.75 22 207.0 TSG-250 145 70 RSHG-25012 ♦

RSHG-3002 3,193 50 456.2 2,280 312 362 310 241.0 197.1 101 177 1 19 180 M16x2 30 184.0 TSG-300 177 81 RSHG-3002 ♦

RSHG-3006 300 3,193 150 456.2 6,839 412 562 310 241.0 197.1 101 177 1 19 180 M16x2 30 232.0 TSG-300 177 81 RSHG-3006 ♦

RSHG-30012 3,193 300 456.2 13,678 562 862 310 241.0 197.1 101 177 1 19 180 M16x2 30 303.0 TSG-300 177 81 RSHG-30012 ♦

RSHG-4002 3,919 50 559.9 2,798 375 425 350 267.0 215.9 114 196 3 27 205 M16x2 30 270.0 TSG-400 196 78 RSHG-4002 ♦

RSHG-4006 400 3,919 150 559.9 8,394 475 625 350 267.0 215.9 114 196 3 27 205 M16x2 36 330.0 TSG-400 196 78 RSHG-4006 ♦

RSHG-40012 3,919 300 559.9 16,789 625 925 350 267.0 215.9 114 196 3 27 205 M16x2 36 421.0 TSG-400 196 78 RSHG-40012 ♦

RSHG-5002 5,114 50 730.6 3,651 419 469 400 305.0 247.9 114 228 3 27 250 M24x3 38 401.0 TSG-500 228 90 RSHG-5002 ♦

RSHG-5006 500 5,114 150 730.6 10,954 519 669 400 305.0 247.9 114 228 3 27 250 M24x3 38 480.0 TSG-500 228 90 RSHG-5006 ♦

RSHG-50012 5,114 300 730.6 21,907 669 969 400 305.0 247.9 114 228 3 27 250 M24x3 38 599.0 TSG-500 228 90 RSHG-50012 ♦

RSHG-6002 5,987 50 855.3 4,274 429 479 430 330.0 267.0 114 247 3 27 275 M24x3 38 474.0 TSG-600 247 103 RSHG-6002 ♦

RSHG-6006 600 5,987 150 855.3 12,823 529 679 430 330.0 267.0 114 247 3 27 275 M24x3 38 565.0 TSG-600 247 103 RSHG-6006 ♦

RSHG-60012 5,987 300 855.3 25,646 679 979 430 330.0 267.0 114 247 3 27 275 M24x3 38 701.0 TSG-600 247 103 RSHG-60012 ♦

RSHG-8002 8,234 50 1,176.3 5,878 474 524 505 387.0 317.0 149 297 3 27 330 M24x3 38 741.0 TSG-800 297 102 RSHG-8002 ♦

RSHG-8006 800 8,234 150 1,176.3 17,635 574 724 505 387.0 317.0 149 297 3 27 330 M24x3 38 880.0 TSG-800 297 102 RSHG-8006 ♦

RSHG-80012 8,234 300 1,176.3 35,271 724 1,024 505 387.0 317.0 149 297 3 27 330 M24x3 38 1,058.0 TSG-800 297 102 RSHG-80012 ♦

RSHG-10002 10,260 50 1,465.7 7,325 564 614 560 432.0 342.9 174 323 3 27 375 M24x3 38 1,062.0 TSG-1000 † 323 120 RSHG-10002 ♦

RSHG-10006 1,000 † 10,260 150 1,465.7 21,975 664 814 560 432.0 342.9 174 323 3 27 375 M24x3 38 1,213.0 TSG-1000 † 323 120 RSHG-10006 ♦

RSHG-100012 10,260 300 1,465.7 43,950 814 1,114 560 432.0 342.9 174 323 3 27 375 M24x3 38 1,439.0 TSG-1000 † 323 120 RSHG-100012 ♦

* Nominal Cylinder Capacity in ton - see kN values for actual capacity

58 † Tilt saddle supplied as standard