Joyce Dayton Jacks: Raise the Roof

The Problem:

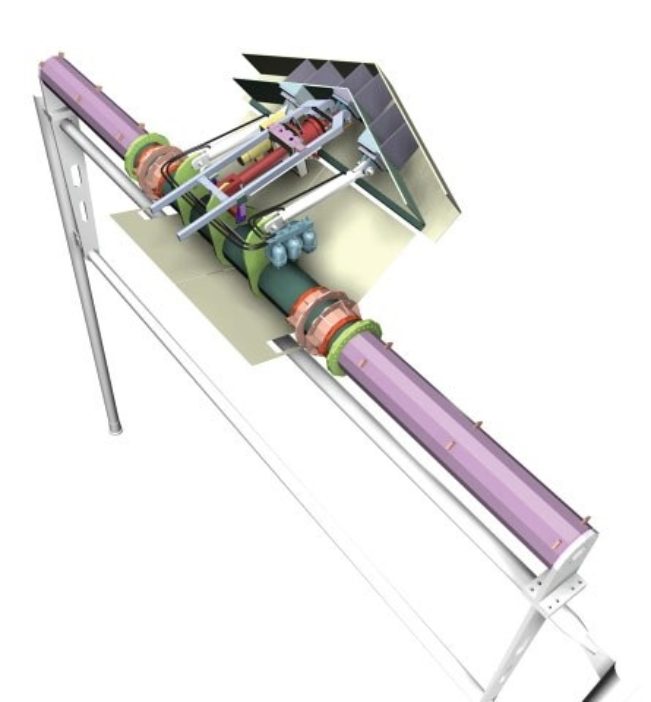

Joyce Dayton was contacted regarding a project to insert a retractable roof structure on an outdoor theatre. The theatre’s director wanted to keep the under-the-stars experience, minus the rainouts, so architects designed a unique opening roof. At the click of a mouse, six triangular panels open in harmony to form a perfect star shape. This project required a solution unlike any in their experience.

The Solution:

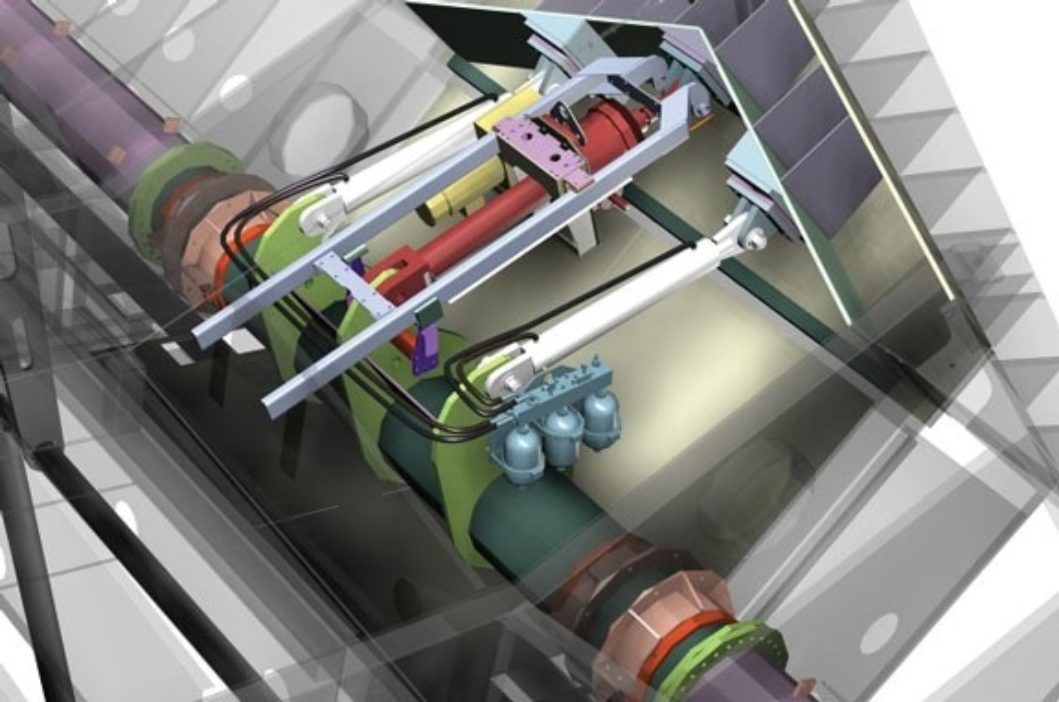

One of the critical components of the solution's success was a 45 Tonne machine screw jack from Joyce Dayton. The 45 Tonne Joyce® jack sits between the roof panel frame and torque tube in a double-clevis arrangement to power each panel. As the machine screw jack extends out, the panel slowly rises to its fully open position. The inherent design of the Joyce® machine screw jack doesn't let it back drive under the weight of the panel alone, as opposed to a ball screw jack. Spherical bearings on the jack end allow the jack to “float”, helping all components stay level throughout the entire motion.

Versatile Joyce® Machine Screw Jacks lift and precisely position loads from 113 Kg to 226 Tonnes. Upright or inverted, these precision jacks operate at full capacity whether the load is in tension or compression, and are self-locking under full lifting capacity. Heat-treated alloy steel worm shafts, aluminium/bronze worm gears, and tapered roller or ball bearings provide rugged reliability. Spherical bearings at each end of the jack allow for any misalignment between roof components.

Starting with a standard “off the shelf” product and adapting it to meet the customer's needs is one of Joyce Dayton's strengths. The Joyce Dayton engineering team is ready, willing and uniquely able to help you design and install a solution to virtually any lifting or positioning application.