alkitronic® CLS2 Pneumatic Torque Wrench/Torque Multiplier

Applications

- Continuous rotation, tightening, or loosening for all heavy duty fastening connections.

- Perfect for bolted applications in hazardous, explosive environments.

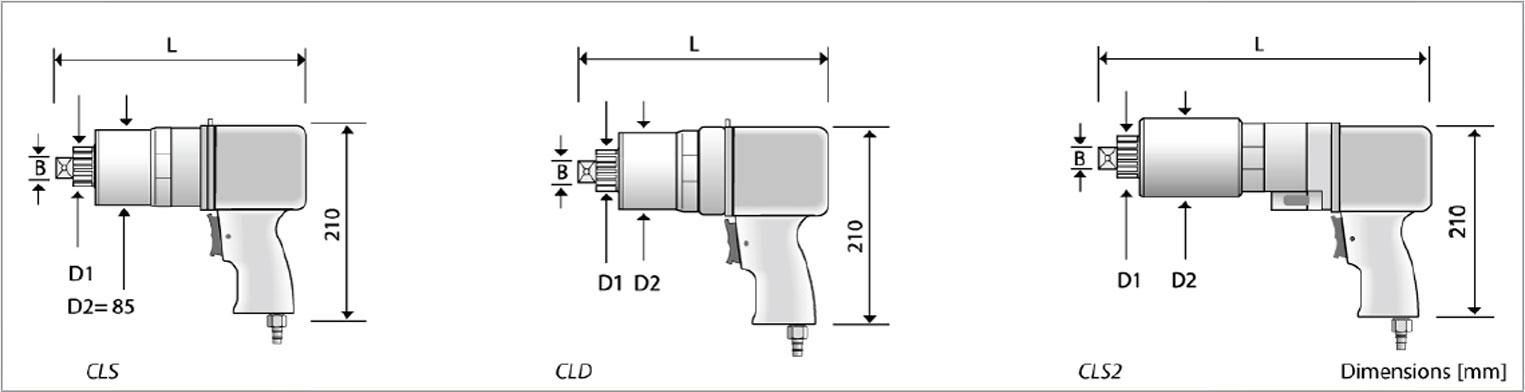

- alkitronic® CLS quick, compact torque multiplier for torques of 55 to1,070 ft.lbs.

- alkitronic® CLD comfortable torque multiplier with rotating handle for torques of 225 to 7,225 ft.lbs.

- alkitronic® CLS2 high-performance 2-gear machine for torques of 90 to 35,855 ft.lbs.

Advantages

- Permanently higher joint quality (compared to impact and hydraulic wrenches) by continuous rotation of the square drive.

- alkitronic® CLD - the 360 degree rotating handle ensures comfortable operation. Barely any reaction forces are transferred to the user. switching to power gear

- (is used for applying the final torque). alkitronic®

- CLS2 with fast gear for turning in and simple, quick switching to power gear (is used for applying the final torque).

alkitronic® Specials

- Simple 1-finger operation for right/left rotation, option to enable thereaction to be locked in one position.

- Robust cast aluminum housing with proven pneumatic drive.

- Proven high-performance gears, produced in a chip-free,

- highprecisionprocess produce high loads with low wear.

- alkitronic® CLS2 with uniquely high torque - 35,855 ft.lbs.

- Optional silencer levels to reduce the noise from the motor exhauston request.

Specifications

On request, you will receive our pneumatic multipliers with ATEX-Certification: II 2 G D c IIB T6

Prerequisites for best work with the indicated torques are an operating pressure of 29-10,000 psi at a volume flow of approx. 122-915 cu.in./min. The torque accuracy depends on the stability of the supply system.

Technical Data Models:

| Type | CLS2/100 | CLS2/150 | CLS2/300 | CLS2/400 | CLS2/600 | CLS2/800 | CLS2/1000 | CLS2/3400 | CLS2/4800 |

| Torque range 2nd gear (approx.) *Nm | 120-355 | 170-505 | 385-1130 | 540-1585 | 840-2470 | 1010-2965 | 1175-3455 | 3310-9720 | 4725-13890 |

| ft.lbs | 90-260 | 125-375 | 285-835 | 400-1170 | 620-1820 | 745-2185 | 865-2550 | 2440-7170 | 3485-10245 |

| Torque range 1st gear (approx.) *Nm | 380-1125 | 550-1615 | 1225-3595 | 1720-5055 | 2675-7865 | 3210-9435 | 3745-11010 | 11575-34025 | 16540-48610 |

| ft.lbs | 280-830 | 405-1190 | 900-2650 | 1270-3730 | 1975-5800 | 2370-6960 | 2765-8120 | 8540-25100 | 12200-35855 |

| Square drive B | 3/4” | 1“ | 1” | 1 1/2” | 1 1/2” | 1 1/2” | 1 1/2” | 2 1/2” | 2 1/2” |

| Diameter (approx.) D1 mm | 41 | 54 | 54 | 72 | 72 | 72 | 91 | ||

| Diameter (approx.) D2 mm | 85 | 85 | 85 | 98 | 109 | 133 | 173 | ||

| Length (approx.) L mm | 330 | 330 | 360 | 380 | 410 | 410 | 430 | ||

| Weight without DMA (approx.) kg | 7 | 7,5 | 9 | 11 | 12 | 16 | 24 | 58 | 58 |

| Idle speed 2nd gearrpm | 36 | 21 | 15 | 9 | 6 | 5 | 4 | ||

| Idle speed 1st gearrpm | 12 | 7 | 5 | 3 | 2 | 1,5 | 1 | further details upon request | |

*) When loosening a bolted connection, up to 20% higher torque may be required (loosening torque). We will gladly advise you with details.